In this course, students are introduced to various methods (processes) for producing metal materials from ores, and then learn the basic reactions based on thermodynamic chemical equilibrium theory and electrochemistry. The aim of this course is to acquire fundamental ideas that can be applied to future technological development by learning the smelting processes and recycling methods of steel, which is a key material that supports industry and our daily lives, and nonferrous metals, which are essential for high-tech products.

Lesson Content

This course is a specialized education course for third-year students and above in the Department of Engineering, Faculty of Engineering. While relearning basic concepts such as chemical equilibrium and oxidation/reduction, the class goes beyond that into specialized content and industrial applications. This time, we covered the fourth lecture out of a total of eight lectures.

In the previous lectures, students learned the concept of understanding the conditions (temperature and surrounding gas composition) necessary to turn ores such as oxides and sulfides into individual metals from the perspective of chemical equilibrium. We started this lecture with a review of the state diagram of alloys, which is necessary to separate different metals from each other.

In the previous lectures, students learned the concept of understanding the conditions (temperature and surrounding gas composition) necessary to turn ores such as oxides and sulfides into individual metals from the perspective of chemical equilibrium. We started this lecture with a review of the state diagram of alloys, which is necessary to separate different metals from each other.

Substances change into three states (solid, liquid, and gas) depending on temperature and pressure. For example, a state diagram of water shows the temperature and pressure at which water becomes ice or vapor. In the field of materials engineering, a state diagram showing what kind of alloys are formed when different elements are mixed in various proportions (whether they mix uniformly and melt together or whether they separate without mixing) is widely used. In this case, it is common to set the temperature on the vertical axis and the mixing ratio (composition) of the elements on the horizontal axis. Since the state diagram is also useful in research aimed at developing superior materials, students in the Materials Design Engineering Course of the Faculty of Engineering have opportunities to study it intensively outside of this course.

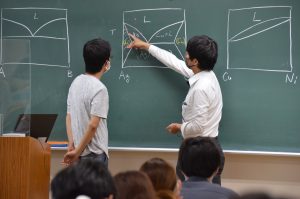

The lecture was based on an original resume and included an explanation of state diagrams for Ag-Cu and Cu-Ni binary alloys. Binary alloys are alloys made of two different elements. Based on the properties of alloys, such as the fact that some combinations, such as silver and copper, are difficult to mix in the solid phase, while others, such as copper and nickel, mix uniformly and easily, the students will consider what kind of reaction will occur when the alloy becomes liquid at a high temperature and is gradually cooled, based on the state diagram. The lecture was based on examples of state diagrams drawn on the board, and was followed by a question-and-answer session with the students.

In the lecture, he explained that the separation of two elements to form a stripe pattern in the solid phase from the liquid phase is called “eutectic crystallization”.

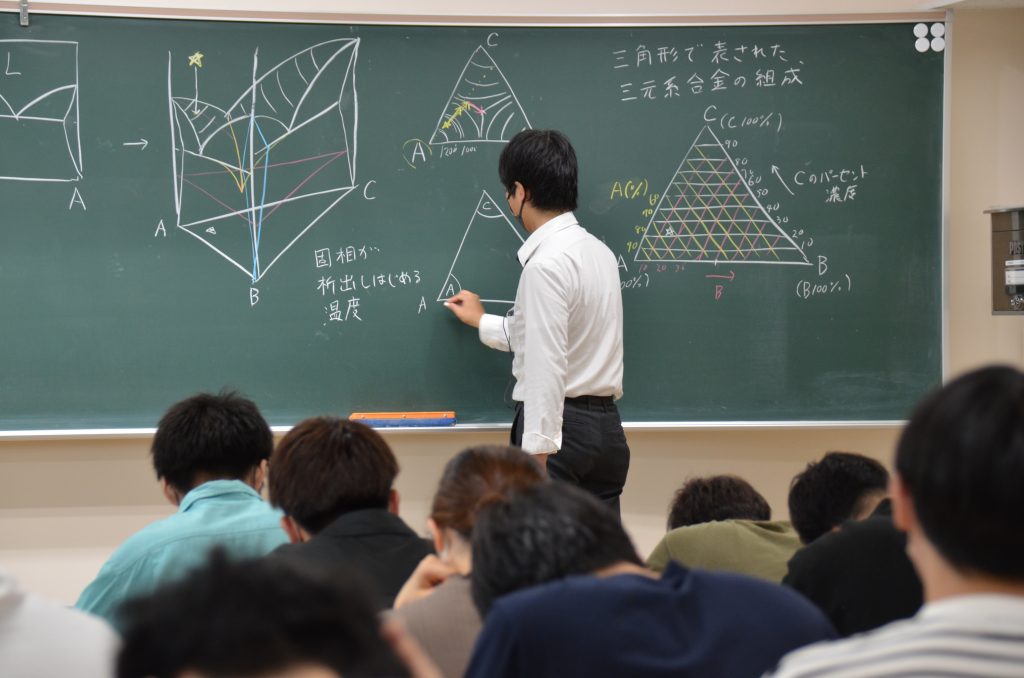

As a further development, a state diagram of ternary alloys was introduced. He explained that the state diagram of ternary alloys, which are composed of three elements, must be considered not only from a planar viewpoint, with temperature on the vertical axis and composition on the horizontal axis, as in binary alloys, but also three-dimensionally, as if it were a triangular prism. Although the content of the lecture was more technical, it was carefully explained in a way that was easy for the students to understand.

At the end of the lecture, students were given exercises to check their understanding of the content of the lecture. The students were able to check their resumes and reference books and concentrate on the exercises.

Since the course was targeted at third-year students and above, the lecture included not only basic content, but also topics that were geared toward graduation research and graduate school admission, allowing the audience to feel the depth of chemistry.

Comments from faculty

You may not be familiar with the term “nonferrous metals,” but it refers to all metals other than steel (copper, lead, zinc, precious metals, aluminum, etc.). Industries in the Toyo region of Ehime Prefecture have a long history of development centered on the Besshi Copper Mine, and I hope that Ehime University students will become familiar with nonferrous metals smelting.

You may not be familiar with the term “nonferrous metals,” but it refers to all metals other than steel (copper, lead, zinc, precious metals, aluminum, etc.). Industries in the Toyo region of Ehime Prefecture have a long history of development centered on the Besshi Copper Mine, and I hope that Ehime University students will become familiar with nonferrous metals smelting.

This class is designed for third-year students in the Materials Design Engineering course of the Faculty of Engineering, and explains the process by which steel and nonferrous metals, which are the materials for industrial products, are made from ores. High school textbooks also explain the smelting process of various metals, but this class takes it a step further and aims to help students understand the process based on the physical chemistry of metals they are studying at university.

Here are my expectations for how I hope this class will help students.

First of all, I would like students who are considering working for steel or nonferrous metal manufacturers after graduation to have basic knowledge and a concrete image of smelting while they are still young, and to use it as a reference in choosing their career path. And I would be happy if that knowledge is of some use in the workplace when they actually find a job.

Students who intend to work in other industries will also be doing research for their graduation thesis during their senior year, and I hope this class will give them some hints when they are preparing their own samples. This is because metal smelting methods are also connected to methods for fabricating various materials such as alloys and ceramics.

And finally, I want students to be aware of the advances in manufacturing as they learn about how metals are made. In the first half of this class, I will explain how metals are made in high-temperature furnaces, such as those that began in the Bronze Age. In the second half, I will explain smelting methods using electrolysis, which have been possible since the invention of electrolysis about 200 years ago. As you can see, the way metals are made has changed over time. As for the present day, it is not only smelting from ores, but also processing recycled raw materials is becoming more and more important. Processes must also be improved in consideration of the environment. I hope that those who become engineers will feel through this class that new ways of making things are emerging and that scientific principles are fundamental in the development of such technologies.

Comments from students

Yuta Kumori, Faculty of Engineering

In the Materials Design and Engineering course in the Faculty of Engineering, students can learn about a variety of materials that are used in products that we come into contact with on a daily basis. While there are many classes on metallic materials in which students learn about the basic properties of metals and the characteristics of practical alloys from a physical perspective, in this course on steel and nonferrous smelting, students learn about the fundamentals of the manufacturing process from minerals to the production of practically viable metallic materials. By understanding the chemical reactions that take place in the process of turning raw materials into materials, students can acquire basic knowledge and concepts for developing new materials, which will be useful for their future graduation research and for future research and development at companies.

In the Materials Design and Engineering course in the Faculty of Engineering, students can learn about a variety of materials that are used in products that we come into contact with on a daily basis. While there are many classes on metallic materials in which students learn about the basic properties of metals and the characteristics of practical alloys from a physical perspective, in this course on steel and nonferrous smelting, students learn about the fundamentals of the manufacturing process from minerals to the production of practically viable metallic materials. By understanding the chemical reactions that take place in the process of turning raw materials into materials, students can acquire basic knowledge and concepts for developing new materials, which will be useful for their future graduation research and for future research and development at companies.

By taking these classes, students can learn about metallic materials that they are usually exposed to without much thought, about the ingenuity involved in their manufacture, and about the characteristics of these materials of which they were previously unaware. One of the charms of the lectures in the Materials Design Engineering Course is that students can feel a connection between what they learn and their daily lives.